Electrostatic Filter for RAM Chimney

In our country, legal activities have started for the purification of textile sourced waste gas upon the increase of the complaints out of the enterprises and increase of the settlement around the industrial areas.

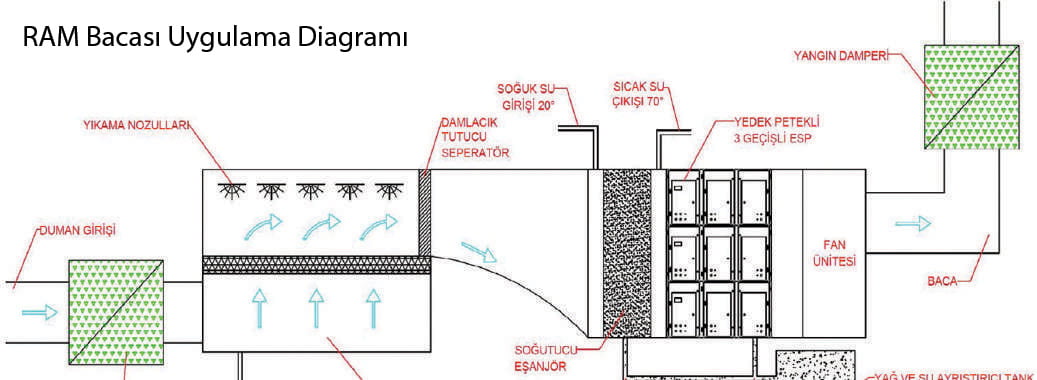

Working principle of electrostatics filter is to create magnetic area with correct flow and high voltage and turn steam into water, turn steam into oil again by condensing any kind of dust, smoke and steam passing from the area on the magnetic shells.

Description

Electrostatic Filter References

Textile Industry RAM – Electrostatic Filters Used for Stenter Smoke

In our country, legal activities have started for the purification of textile sourced waste gas upon the increase of the complaints out of the enterprises and increase of the settlement around the industrial areas.

Working principle of electrostatics filter is to create magnetic area with correct flow and high voltage and turn steam into water, turn steam into oil again by condensing any kind of dust, smoke and steam passing from the area on the magnetic shells.

Any kind of machine or any kind of smoke has their own problems.

Problems and Solutions met at Tentre Chimney Smoke:

1. HIGH HEAT : Electrostatics filters which are sold at the market cannot work above 60 C. Within our production portfolio, electrostatics filters which work at 600 C heats are available. But tentre smoke has burning effect. As the voltage arches have the possibility of inflammation for the smoke that is formed in the electrostatics filter, smoke heat needs to be reduced under the burning heat. Therefore, smoke is cooled with watery heat ex-changer or air heat recycling exchanger. Due to the rare faults at the system caused from the high voltage, in case of coming high heat to the filter, plastic isolators absolutely melt. Therefore, while buying filter, isolators must be known whether they are plastic or not.

2. FLUFF SPECKS : Fluff rare within each type of fabric changes. Fluff rate is nearly zero in the tulle fabrics. But dense fluff rate in the thick and fibrated fabrics cause cooler exchanger and the electrostatics filter cores to get full in a short time. As the fluff specks have the feature of ignition, electric arcs especially occurred in the electrostatics filter may cause fire. Thus, fire occurred in our country where some imported filters were used, we observed that filters completely burned as a result of our services. Therefore, while buying electrostatics filter, close the escape ways with the clauses ‘manufacturing fault- user fault’ in the guarantee clause in the agreement.

3. HIGH STEAM AND RATE OF HUMIDITY: Water vaporizes more than the weight of the fabric during the washing and siliconizing processes at tentre machines, tons of water joins into the smoke. This vapor turns into water without reaching electrostatics filters at 85- 95% rate during the cooling process. This rate changes depending on the heat after the cooling process. In case of the smoke isn’t reduced to the ambient temperature as a result of the cooling process, one part of the condensation happens within the electrostatics filter. This case cause electrostatics filters to take itself protection by closing itself. Working chance of isolator electrostatics filter especially adjacent to the chassis in the tentre machines is nearly zero. This is because; even the most expensive imported product doesn’t work efficient time to time. Horizontal electrostatics filters are produced for insulator metal smoke. Even falling of a piece of water from top core to the lower core cause lower core to take itself protection and close, accordingly it releases smoke.

4. CLEANING AND WASHING: Points to be careful about the cleaning of the electrostatics filters that are used in the tentre chimney; just hot water is not enough for filter cleaning. Even automatic washing machines are being washed manually by taking into the maintenance once in 6 months or annually. Strong chemical oil solvents that are used during the washing cause isolator to be conductive in time by conveying water into the gaps within the ceramic isolators and filter becomes repellency in long term. This duration is 7 years in ceramic isolator filters. Therefore, glass isolator electrostatics filters must be used for tentre smoke.

Except our country, Electrostatics Filter isn’t produced from aluminum. Across the world, it is mainly produced from ALMG 5754 alloy or grooved thin stainless very seldom. In the filters produced from aluminum, sheets get thinner in time and the life of filters get shorter in case of the usage of mordacious for cleaning. Detergent and cleaning chemicals are available for this work instead of mordacious. Even the disadvantage of ALMG 5754 is the weakness against the mordacious, sheets bend and are tensed due to the stainless filter weight. Therefore, collector approaches electrodes to the chassis from the centre. And this reduces the power of filter. Therefore, stainless electrostatics filters are never produced in any European countries. But as there isn’t any other oil solvent chemical apart from mordacious in countries such as Africa and Middle Asia, electrostatics filter from stainless material are produced for these underdeveloped countries.

Electrostatics filters from any kind of material including plastic depending on the demand and need are produced in our firm. (Plastic material is used in acid vapor. Because strong acids melt any kind of metal.) As more than 500 tentre machines are available in our country, a new market has been born.

Since 1989, our firm is produced solutions for the sector and still produces as being the single Turkish firm that has sale and service centers in 4 continents with its long years experience at Electrostatics Filter field. We have never gone out of our sector and we have always tries to define standards and worked to be number 1 in the world at our field. In the beginning, we had had financial loss as we didn’t use the way of suppressing the smell by spraying smell on the smoke which the Provincial Department of Environment permits on tentre chimney. But we did the hypercorrect. We kept smell and smoke by refining the entire smoke and turning waste into usable oil. In the point where we came, we achieved to give maximum hot water from hot tentre smoke to the enterprise or clean hot air within tentre. We are also saving the textile manufacturer to be suffered by repairing electrostatics filters they bring from foreign countries in different countries. No matter which brand your filter is, whether it has spare part or not, we have the proud of being the unique firm that carries out the repair of the any brand successfully and guaranteed.

Our firm produces Electrostatics filter till 100.000 cubic meter and 10Kw. For upper capacities, we are authorizer for sales and service of Siemens products. We have got stronger with the power of Siemens in the problems that we couldn’t solve. Our production is going on to the each points of the world mainly on export on this way.