Open Field Tunnel – Factory Filter

High filtration performance, easy maintenance, low operating costs and various installation options are the outstanding features of Zen Electrostatic air filters for road tunnels.

Description

High filtration performance, easy maintenance, low operating costs and various installation options are the outstanding features of Zen Electrostatic air filters for road tunnels.

After dust is loaded onto the collector plates of the ESP, they are washed with regular water using spray nozzles.

During the cleaning process, the filter modules must be disconnected from the electricity and be voltage-free. It is pre-dried using compressed air through existing spray nozzles to keep the filter downtime as short as possible.

The control system of the filter system automatically starts the cleaning process. The cleaning sequence is fully automatic. It takes about 30 minutes and is usually scheduled during low traffic periods.

Dirty wash water with filter residues is cleaned in a water treatment plant and 90% of the water used can be reused for a new filter cleaning sequence.

The collected filter residues can be discharged to a landfill. Alternatively, due to its high carbon content, thermal use in an incineration plant may be considered.

Depending on sanitary water regulations, the collected wash water can often be disposed directly with other tunnel sewers.

Nitrogen Dioxide Accumulation

An activated carbon filter can be arranged downstream of the particulate filter to remove harmful gases such as nitrogen dioxide (NO2), unburned hydrocarbons (CmHn), ozone (O3) and benzenes from the exhaust air.

This protects 90% of harmful gas components.

It has a very high separation capacity for activated carbon, nitrogen dioxide and other gases.

Specially treated activated carbon absorbs nitrogen dioxide from the air stream. At the same time, some of the nitrogen dioxide is converted into harmless nitrogen and oxygen by catalytic decomposition in the filter.

The filter carbon is formed into cylindrical rods called honeycomb-granules with a diameter of 4 mm.

Thanks to its porous structure, activated carbon has an enormous specific surface area, the active area of one gram of carbon is about 1,000 m². The gas filter is modular like the fine dust filter.

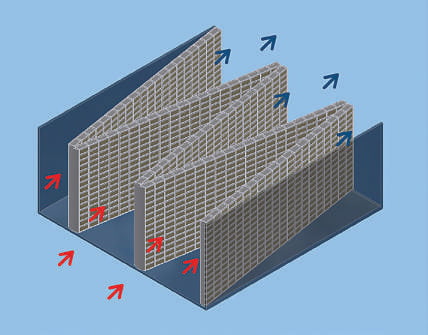

The carbon pellets are packed into rectangular metal cans with two opposing air permeable perforated plates. The filled cans are mounted side by side on a vertical frame, thus forming a closed filter wall. Exhaust air flows through the filter wall.

In order to obtain optimum air flow, the filter walls in the air duct are arranged in a “W” shape.

If the separation capacity of the activated carbon runs out after a few years, the cans are replaced with freshly filled cans. Alternatively, an installation with continuous filter walls is possible.

Malzemeler

Filtre sisteminin elektrostatik tutucu, ön iyonlaştırıcı, boru hattı, nozul ve raflar gibi kirli egzoz havasıyla temas eden tüm bileşenleri ve parçaları, uzun hizmet ömrüne sahip yüksek kaliteli paslanmaz çelikten ve alaşımdan (316L ve ALMG 5754) üretilmiştir.